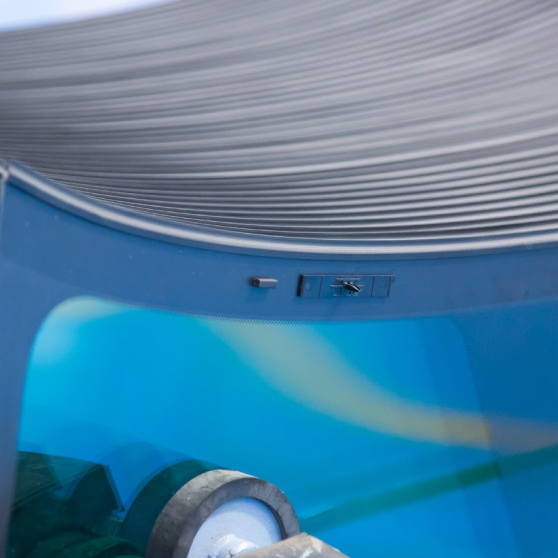

Throughout our history in Vitro, we have continually raised the industry standard through advancements in glassmaking and coating technology. These upgrades have significantly reduced the use of natural gas and greenhouse gas emissions in the glass production process and radically lowered energy consumption in homes as well as commercial buildings.

From the first environmental heat absorbing glass to advancements in automotive glass, at Vitro, we are based on our own previous advancements in glass technology to provide innovative new performance-enhancing glass products, substrates and coatings, to order to meet the needs of end users in a wide range of markets and applications.

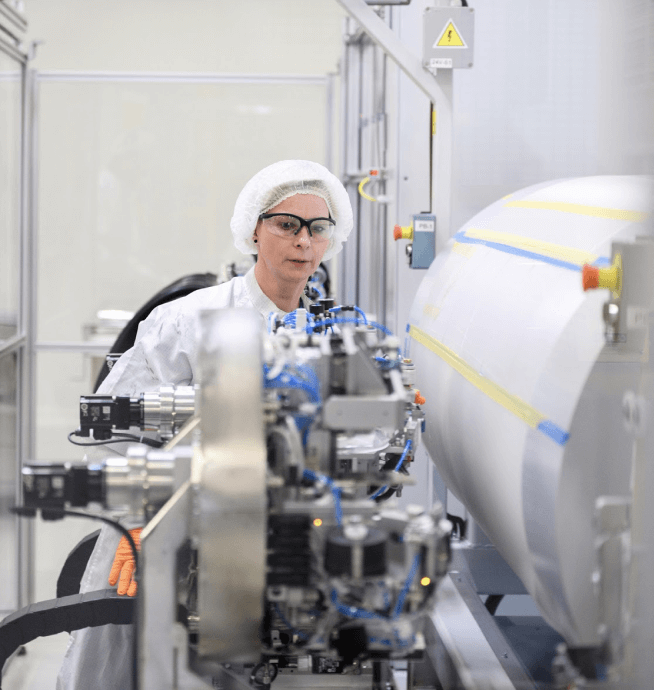

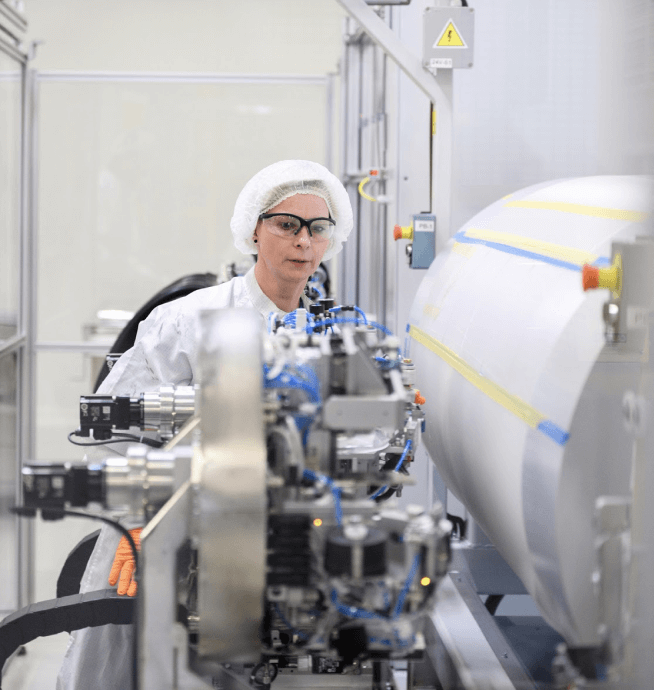

For more than 50 years, the Vitro Glass Technology Center in Pittsburgh, Pennsylvania, has been one of the world’s most sophisticated hubs for glass research, technology and product development. More than 500 patents have been issued to employees of the Center and their collaborators over the past 30 years, more than 200 of which are still active.

Among the innovations developed there are numerous products that have become proven, trusted brands, including Starphire Ultra-Clear® low-iron glass and Solarban® 90 glass, the commercial glass industry’s first MSVD quad-silver-coated low-e glass.

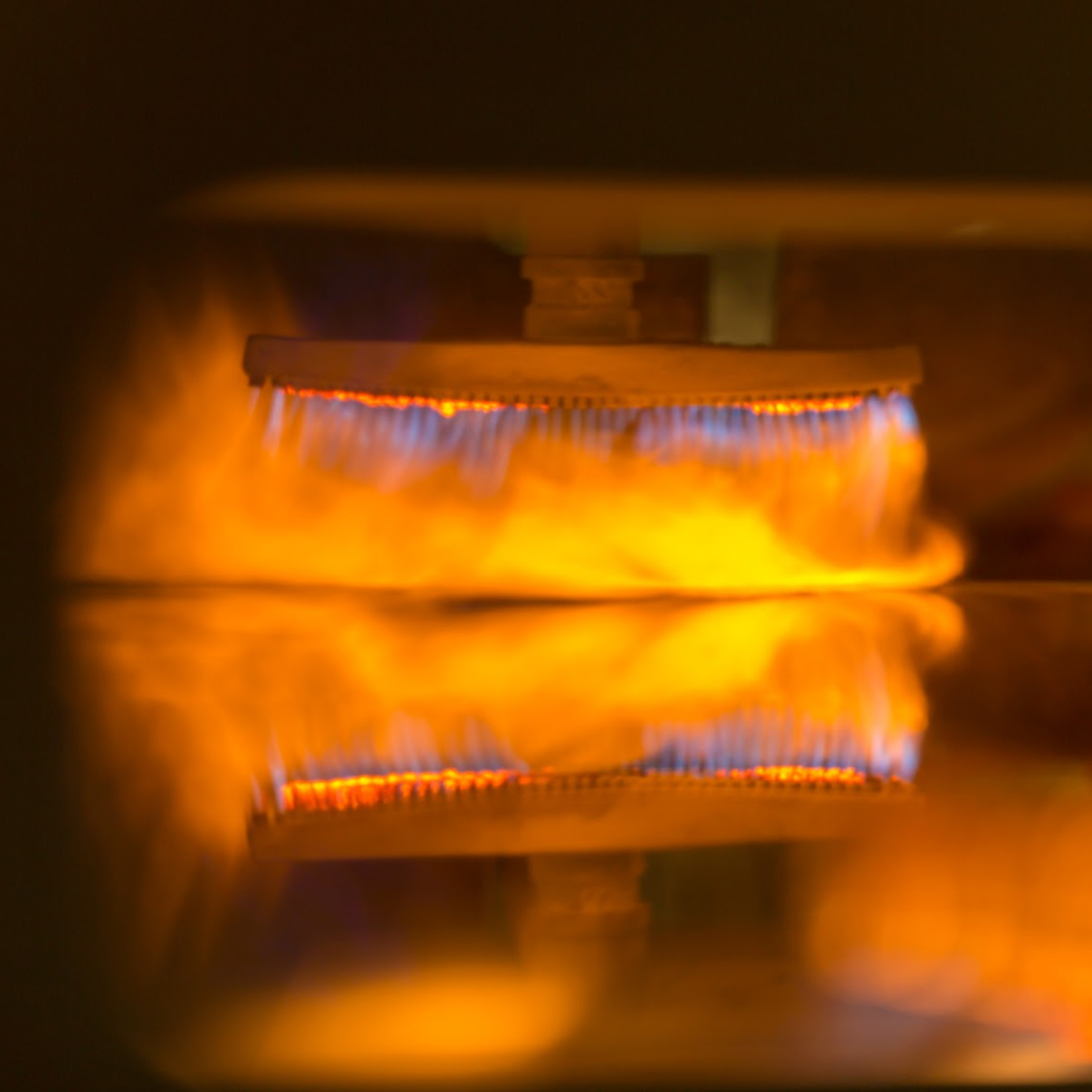

Vitro Architectural Glass also utilizes and licenses proprietary Vitro-owned and patented oxy-fuel furnace technology for glass making. Pioneered and perfected at Vitro’s Meadville, Pennsylvania automotive float glass plant, this technology reduces natural gas consumption by 15 percent, carbon emissions by 10 percent and NOx emissions by more than 50 percent compared to traditional gas/air-fired glass furnaces.

Vitro Automotive strives every day to obtain off-cycle CO2 credits from the Environmental Protection Agency in the United States for reducing solar energy in glazing, which is based on the performance of glass in the areas of fuel efficiency, CO2 emissions, light weight, powertrain technology and aerodynamics.

In addition to Vitro's overall corporate commitment to environmental protection and sustainability, safety and security are also central areas of our technology team. Our job in this area supports quieter indoor environments, greater privacy protection, and UV radiation protection.

FAMA's R&D team is led by highly experienced engineers, electricians and designers who are fully dedicated to research and committed to innovating and developing new products that improve our processes in a wide range of industries.

From the conceptualization to the prototype stage, at Vitro we use industry leading hardware and software technology to excel in diverse industries and disciplines such as 3D modeling, finite element analysis, and manufacturing design.